Types of chemical indicators and their characteristics:

Class 1 chemical indicators

Features

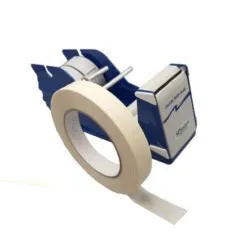

– These indicators are used to detect the sterilization process and are often placed on packages in the form of adhesive tapes or colored labels.

– The color change of these indicators shows that the packaging has been introduced to the sterilization process.

Class 2 chemical indicators

Features

– These indicators are used for special tests such as steam penetration tests and sterilization evaluation.

– They are usually used in steam sterilization devices to check the correct operation of the device.

Class 3 chemical indicators

Features

– These indicators show only one sterilization parameter (such as temperature or time).

– They are used to monitor a specific parameter of the sterilization process.

Class 4 chemical indicators

Features

– These indicators show several sterilization parameters simultaneously.

– Their color change indicates the fulfillment of at least two critical parameters such as temperature and time.

Class 5 chemical indicators

Features

– These indicators have an integrated function and check all the critical parameters of sterilization.

– Their color change is similar to the results of biological tests and indicates complete sterilization.

Chemical indicators class 6

Features

– These indicators have the highest level of control and supervision of the sterilization process.

– More precisely, they examine all the sterilization parameters (temperature, time, pressure) and their color change indicates the achievement of complete sterilization conditions.

Applications of chemical indicators:

Packaging of medical devices

– Using chemical indicators on the packaging of medical devices to ensure that the sterilization process is carried out correctly.

Quality control

– Use in quality control laboratories to check the correct operation of sterilization devices.

Medical centers and hospitals:

– Use in hospitals and medical centers to ensure the sterility of surgical equipment and instruments.

– Dental equipment:

– Use in dental clinics for sterilization of dental tools and equipment.

Reviews

There are no reviews yet.