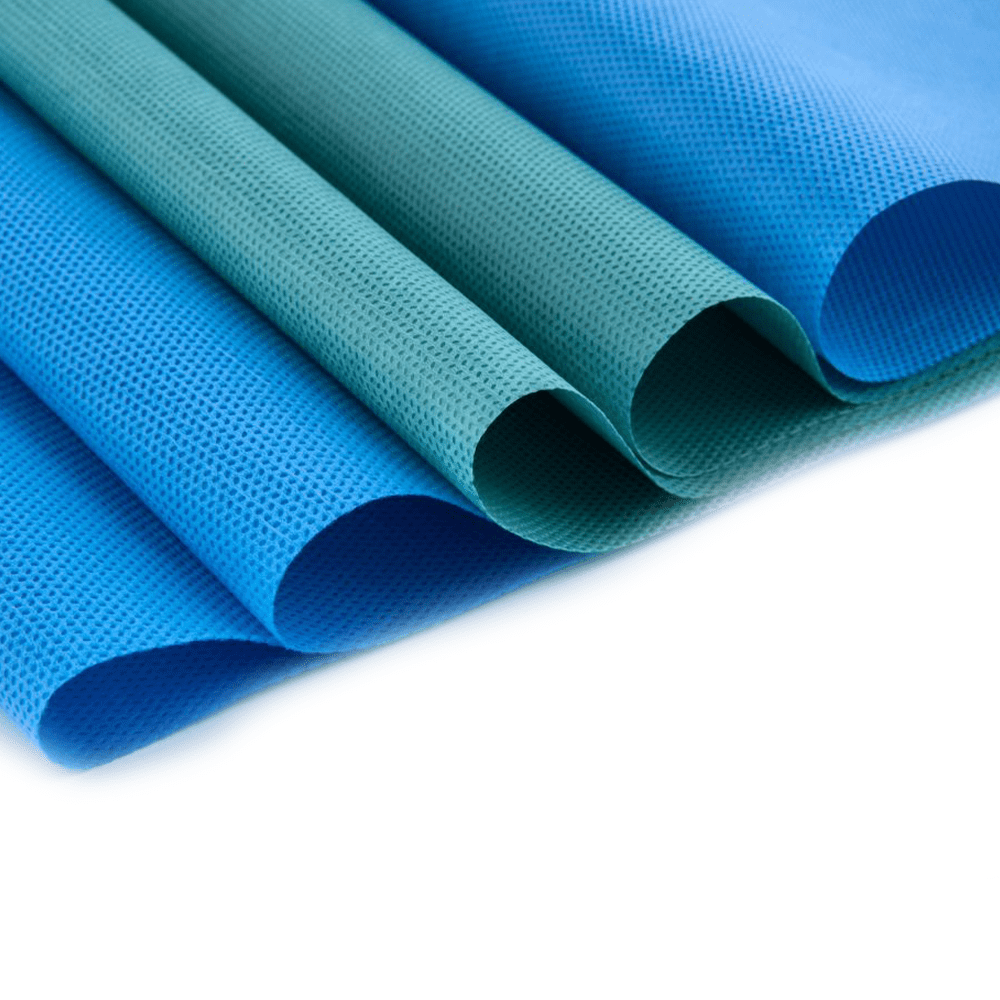

Nonwoven fabrics are produced through a variety of processes such as melt-blown, spunbond, or needle-punched techniques, which create a bonded web of fibers without the need for weaving or knitting. This manufacturing process allows for the production of fabrics with specific properties tailored to different medical applications.

For example, **melt-blown nonwoven fabric** is commonly used in high-performance medical masks due to its superior filtration efficiency, capturing airborne particles and droplets. **Spunbond nonwoven fabric**, on the other hand, is more commonly used for surgical gowns and drapes because of its strength, durability, and fluid resistance.

Nonwoven fabrics are also valued for their comfort. Soft to the touch and gentle on the skin, they help reduce irritation during prolonged wear, which is especially important for patients and healthcare workers who may need to wear these products for extended periods.

Furthermore, nonwoven fabrics are cost-effective, allowing for mass production of disposable medical items that can be safely discarded after use, reducing the risk of infection and improving overall hygiene in healthcare facilities. These features make nonwoven fabrics an integral part of medical protective gear, contributing to enhanced safety, reliability, and comfort in healthcare environments.

Reviews

There are no reviews yet.